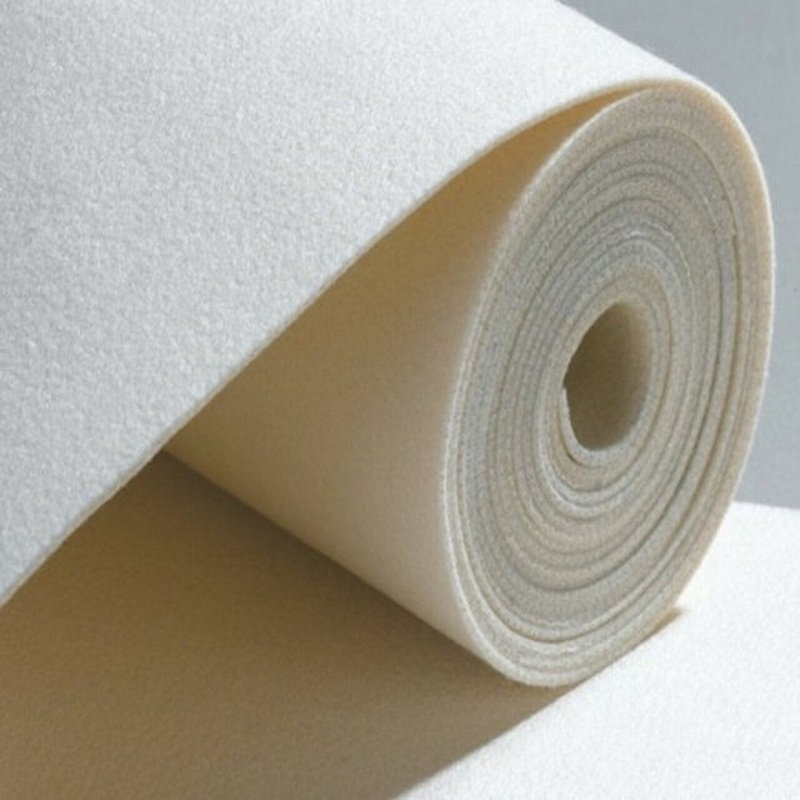

Non-woven filter fabrics are versatile, high-quality materials designed for applications that include sediment control, erosion prevention, and filtration. These fabrics are meticulously engineered to deliver outstanding performance in filtration, effectively managing sediment and preventing erosion. Their adaptability makes them suitable for numerous uses. We provide tailored solutions to accommodate your unique requirements. As a reputable provider, we present an exceptional range of non-woven filter fabrics crafted from the finest raw materials with precise manufacturing techniques.

The application of our needle-punched filter fabrics is comprehensive; addressing the filtration needs of both wet (liquids) and dry (particulates) substances across a broad spectrum of scenarios. Our selection process for fibers and their combinations is critical, ensuring that the resulting needle-punched filter fabrics can withstand environmental challenges, including temperature extremes, exposure to ultraviolet light, and varying degrees of fluids and chemical concentrations. Here are key features of non-woven filter fabric:

• Customizable: Our non-woven filter fabrics can be tailored to meet specific requirements, including weight, strength, and filtration properties.

• High Filtration: The fabric provides excellent filtration, making it suitable for various filtration and separation applications.

• Sediment Control: It is effective for sediment control on hillsides, riverbanks, and construction sites, helping to prevent soil erosion.

• Versatile Applications: Suitable for a wide range of applications, including roadway stabilization, French drain systems, and restoration projects.

• Durable and Resilient: The fabric is strong, flexible, and resistant to UV rays, mildew, and biological degradation, ensuring long-lasting performance.

• Non-Woven Dust Collection Bag Filter Fabric

Our company produces Non-Woven Dust Collection Bag Filter Fabric crafted from durable polypropylene and polyester materials. With a selection of widths and GSM configurations, our filter fabrics are essential for optimal performance in diverse sectors such as pharmaceuticals, automotive, and chemical industries, ensuring efficient dust containment and air quality control.

• Producing Panel Filter Fabrics

We create high-quality Filter Fabrics tailored to Electrical Panels and Generator Sets. These specialized fabrics are designed to maintain cleanliness and efficiency in electrical systems, supporting equipment longevity and ensuring uninterrupted power supply in various applications.

• Air Filter Fabrics for the Automotive Industry

Our thermo-bonded filter fabrics are expertly designed for the automotive industry, enhancing air filtration systems within vehicles. These fabrics are engineered to provide superior dust and particulate-trapping capabilities, improving engine performance and cabin air quality.

• Air Conditioning Filter Fabrics

We offer thermo-bonded filters specifically for air conditioning units to improve air quality and system efficiency. These fabrics are crafted to capture contaminants effectively, prolonging the lifespan of HVAC systems and providing a cleaner, healthier indoor environment.

• Filter Fabrics for Paint Booths

Our Filter Fabrics are meticulously designed for Paint Booths, capturing overspray and contaminants and ensuring a clean and safe working environment. These fabrics are integral to maintaining the quality of finishes and protecting equipment from excess paint build-up.